How To Choose The Best Commercial Ice Maker

After reading the basics of commercial ice maker, we believe that now you have a certain understanding of the main knowledge commercial ice machine, it is time to decide which type of commercial ice maker is best for you.

Table of Contents

1. What styles are available for commercial ice machines?

Commercial ice makers can be divided into four types: modular ice makers, under-counter ice makers, countertop ice makers, and stacked ice makers. Different styles can meet your different business needs. If you are a large-scale commercial ice machine Supermarket owner, your needs may be a modular commercial ice maker, if you are a small bar business owner, the undermount ice maker is more suitable for you! If you’re wondering which ice maker is best for your business, follow us so you can make an informed decision.

A. Modular Ice Maker

Modular ice machines are different from other types of ice machines because they are a cart unit, so to speak. To use a modular ice maker, you’ll need to mount it to a separate container or dispenser. Modular ice makers generally produce the greatest ice production, and they also offer a lot of options in terms of space size, which is why most businesses that require a lot of ice cubes prefer to use modular units. For example, slim modular ice makers can be installed in tight areas, and low-profile modular ice makers are made for low-ceiling workplaces. Also, if you need more ice storage at some point, you can buy a larger ice box without having to buy a whole new commercial ice maker in the process.

Modular ice makers come in a variety of sizes and production speeds, ranging from 45 pounds per day to over 3,000 pounds of ice.

B. Undercounter Ice Maker

How about you are looking for a more compact solution, an undercounter ice maker may be a better solution to your problem, an undercounter ice maker is small in profile, usually less than 41 inches in height, to save space, almost all machines All self-contained units, these types of ice machines are often installed behind bar or restaurant counters and are designed with built-in storage bins so that bartenders and other staff can immediately use their own ice supply. However, it has a much lower output than modular machines, with the largest model yielding around 300 lbs/day, making it a great option for local bars and cafes with low ice consumption.

C. Countertop Ice Maker

Countertop ice makers are designed to be mounted on top of a counter or bar so that ice cubes can be easily accessed by workers. Many commercial-grade countertop units are dispensers that drop ice cubes directly into the container with the push of a button or lever. Overall, these types of dispensers are more hygienic because employees and customers don’t have to manually retrieve the ice. These types of ice machines are very popular at self-service kiosks, sandwich shops, burger joints, and other fast-casual dining establishments. A countertop ice maker is also a great addition to an office break room, and ice cubes are available to many.

D. Stackable Ice Makers

While stackable ice makers are also technically a modular ice maker, they differ in that you can stack multiple units together.

The stackable commercial ice maker is designed for high-volume workplaces where space is limited. Rather than buying two separate modular units, which require two bins, you can install two units to distribute ice into one bin for faster recovery times when dealing with limited space.

There can be some downsides to opting for a stackable commercial ice maker, on the one hand you will need plenty of ceiling space as you will need to stack the machines together, a stackable installation on each side of the unit (including the ceiling) will still require about a foot and a half space, or heat can linger around the machine and cause problems such as reduced icing and machine damage.

Another problem with stackable ice makers is that they are difficult to clean and service. By stacking one unit on top of the other, it’s nearly impossible for you to clean and maintain the bottom unit, at which point technicians are forced to do a full unload to detach the machines and clean them individually. Unscheduled cleaning and maintenance of ice machines can cause recurring problems, resulting in a lower overall lifespan than individual units.

For these reasons, if you can’t find the right space for two separate machines, this is when you should consider buying some stackable units.

2. How to choose the best commercial ice maker

Commercial ice machines have a wide range of uses, and are widely used in catering, large supermarkets and other industries, so how to choose the most suitable ice machine for you? Here are some buying guides.

A. Look at the main components of the refrigerator

Compressor

1) Good compressors have higher internal assembly precision, and can ensure stable performance even in harsh environments.

2) A good compressor takes into account the experience of using the device, reduces noise through noise reduction design, and reduces hearing damage.

3) Good compressor internal parts have better material and lower wear and tear, which can ensure long-term cooling effect.

4) A good compressor manufacturing process is more mature, and a reasonable pressure design can save electricity and energy to the greatest extent.

Condenser

Air-cooled: This is the most popular type of condenser because it uses the least amount of water. It relies on a built-in fan that blows air through the condenser, and you don’t need to install extra wiring to use it. However, your kitchen or bar should have enough space to allow adequate airflow for the machine. Air-cooled commercial ice maker are more energy efficient than water-cooled, with lower operating costs and less waste. However, when they push the hot air out of the commercial ice machine, they push it into the environment where the ice maker is. This hot air can be uncomfortable, especially in tight spaces like kitchens.

Water-cooled: This condenser type draws water next to the condenser’s heating coil to cool it. Like the air-cooled condenser, the entire system is built into the ice maker, but you need a reliable source of cold water. It’s a no-brainer for areas with high heat and poor air quality, but it uses a lot of water. Water-cooled commercial ice makers are the least popular option, as they tend to be noisy and wasteful. Commercial ice machines produce ice around the clock and keep them cold. In order to operate a water-cooled machine, the machine has to filter water through its system to cool it – kind of like a radiator in a car. Excess water is drained from the machine and sent to the sewer line. Not only do water-cooled machines waste a lot of water, they cost the most when employers have to pay to buy water and manage it as sewage.

However, for organizations with limited space to store commercial ice machines, such as small stores in malls, water-cooled machines are a good option. Since water-cooled commercial ice maker don’t produce as much heat as air-cooled counterparts, they may also be more comfortable in small kitchens. While many businesses don’t want to pay extra for water and sewage, water-cooled machines can be cost-effective for businesses with good water systems.

Remote Cooling: Finally, this condenser is installed separately from the ice maker (usually on the roof). Remote ice machines are ideal for facilities that need to eliminate the heat and noise produced by ice machines, especially if you are running multiple systems in the same area. However, if the condenser is installed outdoors, your ice maker is very quiet. This type of cooling system uses a remote evaporator to cool the system. Evaporators are usually stored on the roof of a building or in another room. In this case, the remote cooling system is less noisy and does not generate unpleasant heat.

B. Ice Maker Output

When selecting a model, one of the main points to consider is the amount of ice used. At this time, there will be certain requirements for the amount of ice production and the speed of ice production. The ice production of commercial ice machines varies greatly due to environmental conditions, and it is necessary to determine the standard operating conditions before comparing their ice production. The ice machine adopts the internationally accepted nominal working condition as the standard working condition of the product (that is, the temperature of the ice-making water is 15°C±1°C; the working environment temperature is 21°C±2°C; the power requirement is single-phase 220V 50Hz/ Three-phase 380 volts 50 Hz; water source requirements are clean fresh water; working unit time is 24 hours) .

From the point of view of experience, generally speaking, Chinese restaurants: 0.5kg ice cubes per seat; Western restaurants: 1kg ice cubes per seat; hotel rooms: 1kg ice cubes per room; sand ice, shaved ice per kilogram Serves about 4 cups. Knowing the above data, you can make reasonable choices based on your size and forecast of turnover.

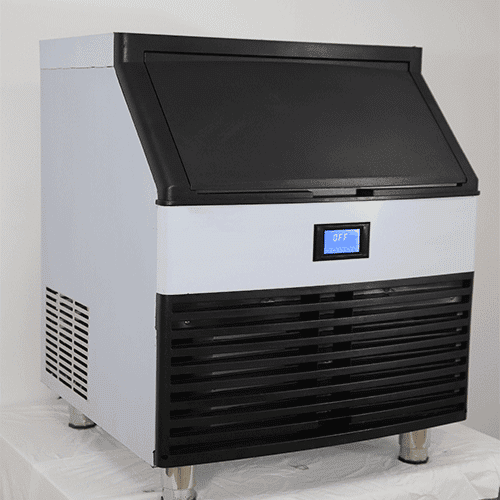

C. Look at the appearance

A quality ice machine, first of all, in the appearance of the material material and workmanship is very careful, it will use the standard stainless steel. After anti-corrosion treatment, corrosion resistance, easy to clean, long service life. If the surface has stains and water stains, a timely wipe with a rag, immediately become as clean as new. The use of plastic parts made of overall injection molding, because only in this way, it will make it beautiful, durable, strong, not easy to deformation. From the external production process, the stainless steel edge used for articulation is smooth and does not scratch your fingers when you touch it, while the articulation gap is even, beautiful and the base plate is thick and not sunken. The cheap ice machine, the material used is mostly non-standard, even cheap thin plate, plate processing material technology is rough, poor corrosion resistance, easy to deformation.

Summary

Ready to start your ice making business now? Contact Chefmax, we have over 20 years of experience in the refrigeration equipment manufacturing industry and will recommend the best ice machine for your needs and create an efficient restaurant for you!