Using a Commercial Blast Chiller in Your Restaurant Kitchen

Is there a safer and more hygienic way to cool food than using a refrigerator or freezer? The answer is to use a commercial blast chiller. For the most part, we think of a refrigerated or freezer cabinet as being sufficient for all storage needs in a commercial kitchen, but in recent years, the need for safety, speed, and sanitation has led to the use of the blast freezer in more and more commercial scenarios, even though it cannot store food for long periods on its own. So why it will gradually take an important role in the kitchen, this article will share all the necessities of using a blast chiller.

Table of Contents

1. What is blast chilling?

Blast chilling is the rapid freezing of food from 70℃ to 3℃ in 90 minutes or from 70℃ to -18℃ or even lower in 240 minutes. Compared with ordinary cooling, blast chilling can effectively slow down the growth and activity of microorganisms and enzymes to ensure safety and hygiene.

Compared with traditional slow freezing methods, the main advantage of blast chilling is that it reduces the temperature of food faster, reducing water loss and cell rupture without damaging the internal structure of the food. Blast chilling forms more minute ice crystals than normal cooling, and these ice crystals do not cause quality loss when heated, better preserving the taste, nutrition, and quality of the food.

2. Can the blast chiller kill bacteria?

Most bacteria will be inhibited from moving at low temperatures, but low temperatures do not kill bacteria, only high temperatures, and ultraviolet light can kill most bacteria.

The good news is that the commercial blast chiller can slow down the reproduction rate of bacteria. Bacteria will grow actively between 63°C and 5°C, and the time food is in this temperature range needs to be shortened to ensure hygiene. Ordinary commercial refrigerators usually take several hours to cool down to refrigerated or frozen temperatures, during which time bacteria will multiply rapidly, putting food at risk of spoilage.

Blast chilling rapidly cools food to very low temperatures (usually -18°C or lower), which greatly slows the growth and multiplication of bacteria and other microorganisms compared to regular refrigerators, which can help maintain food quality and extend shelf life.

However, when blast-chilling food is thawed, bacteria can still multiply under the right conditions if it is not properly heated or treated, so it must be thoroughly heated or treated according to food safety standards before consumption.

3. What are the application scenarios of the blast chiller?

A. Hotel

Hotel food and beverage supply needs to follow the three principles of fast, high quality, and variety of categories, food, and beverage is an important part of measuring the level of hotel service. Blast freezers can help the hotel cool from vegetables, meat, and seafood to desserts and other different kinds, of ready-to-use fresh vegetables for customers to process food, whether it is a buffet breakfast or hotel dinner.

Including the hotel in the batch production of soups, a large number of soups is difficult to cool, ordinary freezers can not directly into the hot soup, but wait for them to naturally cool down and will breed bacteria, so the blast chiller is the best choice, you can directly into the hot soup without worrying about an excessive load on the refrigeration system.

B. Noodle store

Buns, dumplings, steamed buns, dumplings, and the fillings in them can be cooled and stored for a short period in the blast chiller. It is well known that these doughs need a certain time to wake up, and the blast chiller can preserve the dough to avoid over-waking or store the freshly formed dough until the next day without destroying the yeast activity.

C. Food processing plant

Blast chiller in food processing plants mainly plays a role as the front end of cold chain transport. Food processing plants usually use large quick-freeze cabinets to batch quick-freeze various meat, aquatic products, and fruit products and then transported them around the system through the cold chain transport vehicles, this operation can effectively extend the shelf life of processed products, reduce the risk of spoilage in the process of transportation and distribution, and maintain the flavor and taste.

D. Ice Cream Processing

The commercial blast chiller can improve the efficiency of ice cream making. After the ice cream mixture is removed from the mixing bowl, the blast chiller can quickly harden them for unpacking, and transfer them to the freezer or display counter for selling.

E. Dessert stores, bakeries

For making juice sorbet, ice cream, and other soft frozen desserts, it can be used for quick setting and also for releasing products such as mousse and keeping the surface of the product smooth. Dessert stores can also use the blast freezer to cool perishable ingredients such as fruits.

F. Seafood outlets, fishing boats

For fragile aquatic products, the use of general freezers will damage the internal structure of the food, the formation of larger ice crystals, thawing the ice crystals melt, so that the food loses quality and taste, and even the phenomenon of “frozen cooked”, for the quality of aquatic products have a great impact. Blast chiller can preserve the flavor of precious seafood, avoid moisture loss and bacterial growth, maintain the freshness and quality of food, and its nutrients can also be maintained.

Many fishing boats are equipped with blast chillers to quick-freeze and transfer the salvaged fresh aquatic products and seafood to cold cabinets for storage so that they can remain fresh after being transported ashore to the selling place.

4. Why is a blast chiller better than a regular refrigerator?

A. Faster cooling speed, inhibit bacterial growth

As mentioned above, the cooling speed of ordinary refrigerators can make food in the dangerous temperature range where bacteria are actively growing for a long time, which can pose a threat to food safety and hygiene in commercial kitchens. With its powerful cooling capacity, the commercial blast chiller can shorten the time when food is in a dangerous zone, providing a guarantee for subsequent safer storage.

B. Can be lowered to lower temperatures

The lowest temperature that can be reached in a blast chiller is lower than in a regular refrigerator, usually -45°C, compared to -18°C, which means that the blast chiller can cool the inside of the food faster, reducing handling and waiting time.

Deep-cooling type of blast chiller can reach -80℃ (some custom models can be cooled down to -90℃), this type of blast chiller is more suitable for low-temperature preservation of reagents, drugs, and seafood, and is used in biomedical scenes, research, and science units, etc.

C. You can put in hot food for cooling

Ordinary refrigerators are not allowed to put in hot food, which will not only put too much load on the refrigerator’s cooling system but also affect other food stored in the refrigerator by raising its temperature (ordinary refrigerators have no way to consume these temperatures in a shorter period), increasing the risk of spoilage. In addition, putting in hot food may also increase the humidity of the air in the refrigerator, increasing the risk of bacterial growth and reducing the freshness of other foods.

These problems are easily solved with the blast freezer because it has a more powerful cooling capacity and faster refrigeration, which means you don’t have to wait for food to cool, especially for soups that are harder to cool down.

The disadvantage of the blast chiller is that it cannot be used for long-term storage, which is determined by the nature of the quick-freeze cabinet, which only provides quick cooling and short-term storage. This feature requires it to be used with a regular refrigerator, where the cooled food can be transferred to a regular refrigerator for long-term storage. The ingredients treated in this way can be stored for a longer period and with less risk of disease than if they were stored directly in a regular refrigerator.

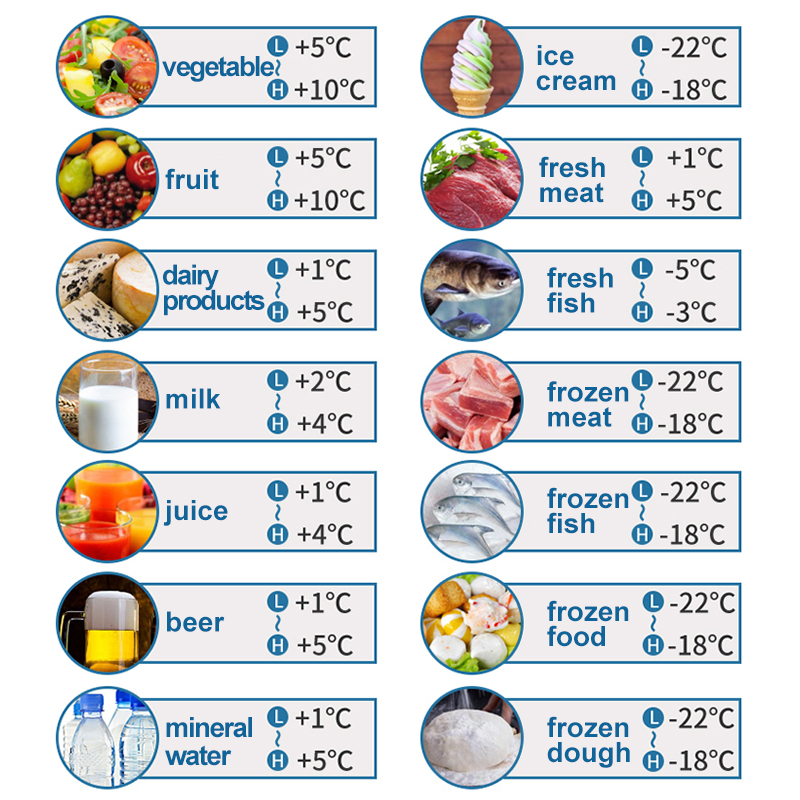

5. Suitable storage temperature for common ingredients

In use, you can freely adjust the temperature of the blast chiller to different food types.

• -45℃ for normal refrigeration mode, which is suitable for food without special requirements.

• +3℃ for products that need to be frozen quickly (e.g. some vegetables and fruits).

• -18℃ for products that need to reach freezing effect quickly. At the same temperature, most blast chillers will provide soft-freeze mode, which is more gentle cooling and more suitable for products with thin and easy-to-crack skin (such as dumplings, buns, dumplings, etc.).

• -80℃ for products that need to reach freezing effect quickly. Suitable for low-temperature preservation of biomedicine, special ice cream, aquatic products, seafood, and tuna, etc.

It is worth noting that just because the blast chiller shows that it has cooled down to the specified temperature does not mean that the internal temperature of the food is also the same. For larger food, it will take 30-60 minutes to lower the internal temperature to the specified temperature. A temperature probe can help you see when the internal temperature of the food has cooled down, and this is a key point to consider when choosing a blast chiller.

6. Summary

A good blast chiller is an important assistant for your kitchen, it provides fast and safe cooling and is widely used in hotels, pasta restaurants, food processing plants, and bakeries. If you need more professional information about commercial blast chiller, please contact Chefmax, we will provide a positive response and a detailed reply.