How to Choose the Walk-in Refrigeration for Your Business

The walk in refrigerator is an essential piece of equipment for most large food service establishments. It has a very large space and is insulated and enclosed, which ensures that your food stays cold and inhibits the growth of bacteria and keeps it fresh. Unlike regular refrigerators, walk in refrigerators are walk in units that allow you to easily access your products and are perfect for restaurants, hotels, supermarkets or any other place that needs to store fresh seafood, frozen or pre-cooled food. How to choose the best walk in refrigeration, please check the Chefmax buying guide.

Table of Contents

1. What are the 5 types of walk in refrigeration?

Fresh walk in refrigerator: the temperature is usually 0℃-5℃, mainly used for preserving vegetables and fruits. The suitable and stable low temperature environment ensures that their freshness and nutrition are not lost, and can maintain the original quality of agricultural products to the maximum extent. Suitable for fruit and vegetable planting, transportation, storage and other scenarios.

Walk in cooler: The temperature is usually -15℃~-18℃, which is used to store bulk refrigerated food or larger items that need to be cooled, as short-term or long-term storage of products. Mainly applicable to meat, aquatic and other food storage. Usually shelves are designed for easy access and effective use of storage space, at the same time, in order to preserve fresh food storage, the temperature should be reduced to -15 ℃ below, the higher the freezing rate of food, microorganisms and enzymes basically stop activities, growth, oxidation is also very slow. So the food can be stored for a longer time, and have better quality. In addition, refrigerated food also requires the temperature inside the warehouse to be relatively stable, excessive temperature fluctuations will cause food spoilage.

Walk-in freezer: The temperature is usually -20℃~-25℃, which is lower than the freezer temperature, mainly used for long-term preservation of seafood, ice cream and other frozen dairy products. The working principle is the same as that of the freezer, but the freezer uses various refrigeration equipment to keep the room at a certain low temperature to ensure the taste quality of seafood, ice cream, etc., but also to extend their freshness length.

Dual temperature cold storage: is the combination of Walk in cooler and Walk-in freezer both, the temperature is usually 0℃-5℃/-18℃. The design can meet your requirements for different food temperature storage.

Walk in blast chillers: The temperature is usually below -30℃, which can reduce the temperature of food to a lower temperature quickly. Compared with walk-in freezer, one of its remarkable features is that the cooling speed is quite fast, the speed is about 10 to 12 times faster than the speed of the cold zone of ordinary cold storage, the temperature and humidity have more strict requirements, and its refrigeration equipment and insulation materials The cost is also much higher than ordinary cold storage.

2. How to choose the best walk-In refrigeration

Foamed-In-Place Polyurethane: This is the most common material used for the interior of vaulting panels and has excellent insulation. Its dense surface layer and closed-cell inner layer have a much higher thermal conductivity than Extruded Polystyrene, and therefore have better insulation performance. At the same time there is no complex construction process, generally after a simple technical training can be completed, the insulation material set insulation, waterproof, fireproof, heat insulation function as one. It is a quality choice for most of the business owners who need walk in refrigeration!

Extruded Polystyrene (XEPS): Generally has good resistance to moisture, even in wet environments can maintain good insulation performance, the material is a more affordable solution in terms of upfront costs, but in the long run may consume more energy.

Laminated Panels: This type of insulation usually uses polyurethane panels that are glued to the inside of the equipment panel. The disadvantage of using laminated panels is that the insulation may peel off from the metal panels.

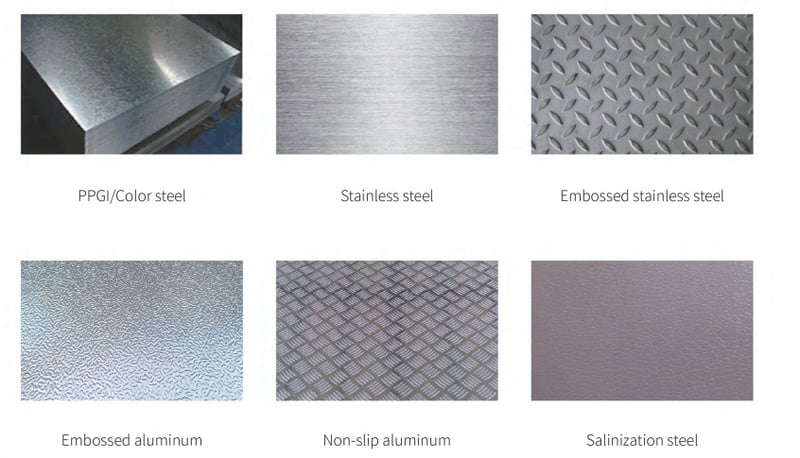

The exterior of the library panels are usually made of stainless steel or embossed aluminum panels, etc. The design of the interior and exterior of the library panels ensures the stability of the temperature inside the walk in refrigeration, and is more energy efficient, improving the efficiency of the cold storage. The thickness of the cold storage panel is usually the thicker the better the insulation effect, the more excellent the ability to resist pressure and bending, the optional thickness is usually 50/75/100/120/150/180/200mm. the following are several panel materials.

Galvanized color steel plate: The optional thickness is usually 0.3mm~0.8mm, the cost is relatively low, and the corrosion resistance is slightly weaker.

Stainless steel plate: The optional thickness is usually 0.5mm~3.0mm, which is the highest corrosion resistance among all finishing materials and is ideal for areas with high traffic.

Embossed stainless steel: Thicknesses available are usually 1mm~3mm.

Embossed aluminum plate: optional thickness is usually 2mm~3mm, anti-slip is better than stainless steel.

Anti-slip aluminum plate: optional thickness is usually in 2mm~4mm, the best anti-slip material.

Salted steel plate: suitable for storing food with high salt content, good anti-corrosion.

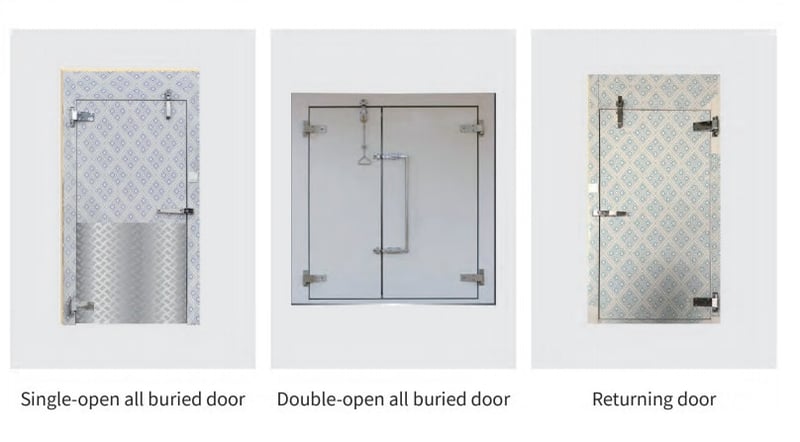

The walk in refrigeration door is also an important point for you to consider as it is the most commonly used part of your facility to provide easy access for employees to retrieve items while placing cold air spills, therefore, the walk in refrigeration must be constructed to withstand frequent use. Here are two common door designs.

Hinged doors: Adjustable door hinges are made of plastic profiles combined with metal panels to form a shell, and the interior is molded with high-density flame retardant and environmentally friendly polyurethane foam for superior sealing and heat insulation and easy installation, ensuring that your cold room can always maintain a cold, stable and uniform temperature, thus improving energy efficiency, suitable for small and medium-sized cold rooms, you can also choose between semi-buried or fully buried doors.

Figure.

Sliding door: usually can be divided into manual sliding door or electric sliding door, good sealing effect and its long service life, with internal off-line escape device, safe and convenient, suitable for medium and large fresh storage, freezing storage or quick-freezing storage.

Other special doors: usually there are air conditioning doors, display cabinet glass doors and laboratory doors, you can contact Chefmax to customize the type of doors you need.

Compressors, condensers and evaporators are the three most important systems in a refrigeration system. A quality refrigeration system will ensure that your cold storage operates more efficiently, with less noise and a longer life span. You will choose a refrigeration system based on how it fits into your building footprint. The two main options are internal side- or top-mounted refrigeration systems, or remote systems. A remote cooling system can be installed on the roof or in some exterior area where hoses provide the cool air delivered to the system through ducts. Again, this choice will depend on how much space you need, and how permanent you want the installation to be. As you might imagine, installing a remote cooling system on the roof means that you will probably use the system for a long time. On the other hand, a smaller prefabricated model with an internal cooling unit will be easier to change if needed.

It is important to understand the difference between indoor and outdoor use. Often the difference is that the installation location will have a different configuration. If you plan to install the walk in refrigerator indoors, keep in mind that changing the unit will take up a lot of indoor space and you will need to set aside more space. This type of installation also generates a lot of additional heat to power the refrigeration system, which may not be the best choice for you if your restaurant is located in a hot and humid environment. If used in an outdoor application, the walk in refrigerator requires an additional roof panel for the unit, which means you may pay more, but it does not release additional heat, which makes it convenient to receive take-out.

A useful way to gauge how much walk in refrigerator space you need is to look at what and how much food you need to store, which in our experience can hold about 28 pounds per 1 square inch of stock space. The smallest cooler units typically occupy 15 cubic meters. But remember, not every square foot of interior space is available. You will also need to consider airflow, aisle space, shelving and racking configurations. If you plan to use carts for bulk items, you will need to allow 40 inches of aisle space to accommodate the carts. All in all, you will have approximately 60% to 70% of the interior space available.

For a walk-in to operate effectively and efficiently, you need to make sure it has enough space to allow for proper air circulation. Your walk-in should allow at least 1″ of space between the exterior of the walk-in and the walls and ceilings of the building. If using a top mounted compressor, allow at least 2 inches of space between the top of the compressor and the ceiling.

3. How to maintain and clean walk in refrigeration

It is vital to keep walk in refrigeration in top condition, and regular maintenance and cleaning is an important part of this process, which also extends the life of the unit.

1. Shell structure

Check the structure of the cold storage regularly. In the case that the insulation layer is damaged or the steam insulation layer does not closely overlap with the top waterproof layer, the water vapor in the high temperature and high humidity environment outside the cold storage in summer moves from the high temperature outdoor side to the cold storage under the action of the steam partial pressure difference, resulting in a large amount of condensation or frost layer in the enclosure structure of the cold storage, which affects the service life of the cold storage. So you need to clean it regularly.

2. Refrigeration unit

A. Compressor: Refrigeration unit compressor needs to be repaired or replaced due to high and low pressure gas leakage or long-term use leading to failure and performance degradation.

B. Refrigerant: regularly check whether the refrigerant in the refrigeration system is insufficient. Insufficient refrigerant in the system will lead to a decrease in the refrigeration capacity of the cold storage and a decrease in the working pressure of the unit (increased frosting), check whether there is refrigerant leakage in the system. If there is leakage, refill the refrigerant in time.

C. Lubricating oil: The lubricating oil in the refrigeration unit can lubricate and cool the compressor. Long-term use of lubricating oil in the unit will lead to its failure. At the same time, the circulation of refrigerant in the system will carry part of the lubricant from the compressor into the evaporator, condenser and tank structure, resulting in the lack of compressor lubricant on its inner surface or bottom. Therefore, it is necessary to change the lubricant regularly.

D. Filter drier. The function of the unit’s filter drier is to remove moisture and metal debris from the refrigerant in the system to ensure that the system does not become clogged with water or dust. The refrigeration system needs to replace the filter drier or its cartridge periodically.

3. Evaporator

A. After long-term use of cold storage evaporator, the heat transfer surface frost is too thick or too much ash accumulation, resulting in the evaporator heat transfer coefficient reduced, affecting the heat transfer effect, increasing the work load of the unit and increasing the cost of electricity consumption. Therefore, it is necessary to regularly clear the frost and dust on the heat transfer surface of evaporator, regularly clean the heat transfer tube of evaporator, and clear the internal oil dirt.

B. Check regularly whether the evaporator fan can operate normally and whether the operation direction is correct.

C. Check whether the evaporator of the cold storage is dripping and whether the drainage pipe is frozen, blocked or polluted.

4. Condenser

The evaporative condenser and air-cooled condenser of the general refrigeration system are arranged in an outdoor open and ventilated place. After long-term operation, the heat exchanger’s heat transfer effect is greatly reduced due to dust and oil stains on the outer surface of the heat exchanger and lubricant and air on the inner surface. Clean the inside and outside heat exchange surfaces of the condenser regularly.

5. Pipeline

Low-temperature refrigerant or refrigerant is carried in the pipes of the cold storage refrigeration system, whose temperature is generally about 10 lower than that of the cold air in the walk in refrigeration. Damage to the pipe insulation can lead to condensation or frost on the surface of the pipe. Regularly check whether the surface temperature is normal and the structure is intact.