Качество, вкус и индивидуальный подход: мастерство кабинета сухого вызревания Chefmax

Chefmax customized a dry aging cabinet for a restaurant located in Tbilisi. It makes for a stunning presentation while easily and safely producing dry aged beef.

VOI Cuisine, located in Tbilisi, Georgia, is a renowned restaurant that specializes in American, Caucasus, and Georgian cuisine. Their most beloved signature dishes are succulent steaks, including ribeye and fillet steaks. These delectable steaks have gained such popularity that the restaurant requires a daily supply of at least 150 pounds of dry-aged beef.

Dry aging involves allowing beef to ferment naturally for a long time under certain conditions to increase its flavor and texture. But aged beef often costs four times or more than fresh beef. Considering the cost, the restaurant owner decided to buy a dry-aging fridge and make aged beef himself.

The Advantage: Quality Meets Affordability

When VOI Cuisine came time to Chefmax, the restaurant owner stated the problem and need. Though the quality of some aging cabinet specialty brands is trustworthy, the price of the equipment and multiple customizations (including capacity, four-sided glass doors, hooks, restaurant signage, etc.) were too high.

VOI Cuisine took a fancy to Chefmax’s years of experience in equipment manufacturing and a lower customization quote, but they had doubts about the quality of the equipment.

Regarding VOI Cuisine’s most concerning issue – meat aging loss, Chefmax pledged that the equipment could control meat quality loss within 10%-15% during a 30-day aging period. This standard was far lower than the 30% loss caused by typical aging cabinets, resulting in significant cost savings. To demonstrate that they could offer equivalent quality at a lower cost, Chefmax provided extensive data and quality certifications.

In terms of quality, the core components of the dry aging cabinet come from well-known German brands – including temperature control systems from Siemens and compressors from Secop. These reliable components enable the unit to create a standard aging environment within the range of 0-4°C temperature, 62-85% humidity, and 0.5-2m/s airspeed. These data are consistent with the guidelines of the U.S. Meat Export Federation.

In addition, to ensure food safety, Chefmax has installed a UVC system in the dry age fridge. The system is activated every three hours with a continuous five-minute exposure to ultraviolet short waves, eliminating all potential bacteria or pathogens.

After gaining VOI Cuisine’s initial trust with professional information, Chefmax promised to complete all the customization options the restaurant owner needed within a minimal budget, which ultimately led to a exemplary partnership.

Customization: The Art of Attention to Detail

First, the visual appeal is paramount. Conventional dry aging cabinets have a single glass door. While this allows for convenient observation of the meat’s condition, it also attracts customers, enhancing the restaurant’s competitiveness. VOI Cuisine wished to have a fully transparent glass on all sides of the customized equipment for a prominent display near the entrance.

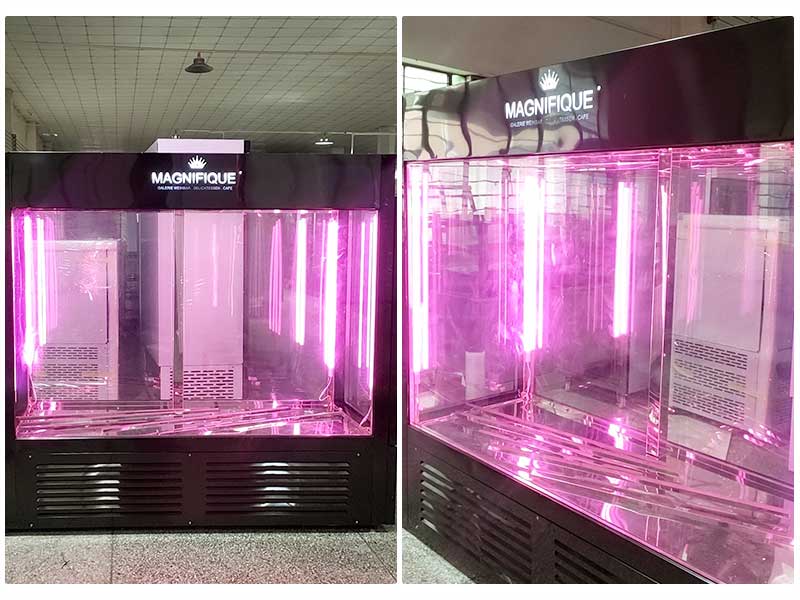

Chefmax technicians used double-layer hollow tempered glass, which ensured structural strength and visibility. The equipment has also been added with anti-fog coating and an electric thermal defogging function to prevent fog from affecting the viewing effect. Lighting is another customized option to enhance visual appeal. VOI Cuisine opted for purple LED lighting, as it accentuates the vibrant and appealing colors of the meat.

Additionally, customization regarding appearance include equipment colors and restaurant logos. To match the classic decoration style of the entire restaurant, VOI Cuisine chose a black titanium alloy shell. The addition of VOI Cuisine’s logo further personalizes the cabinet, which helps enhance the restaurant’s branding.

Excellence in Detail: User-Friendliness

Chefmax successfully manufactured and delivered the dry aging cabinet to Georgia within budget and at the fastest pace. VOI Cuisine was very pleased with how the device worked, and they also provided feedback on details regarding ease of use.

“Thanks to Chefmax’s user-friendly interface, it’s easy for the average employee to age meat.” The owner said. Employees only had to input the correct temperature and humidity parameters to ensure perfect results every time. Maintaining product consistency as they expanded their business, user-friendliness became paramount for VOI Cuisine.

If you have questions about kitchen equipment and layout design, связаться с Шефмакс for a free professional consultation.